Making some noise

Working with vintage computers has many aspects and one of them, nearly throughout every component, is noise.

Hard-drives whirr, floppy-disks rattle, the CRT emits a high-pitch whistle and on top of it all at least one fan is blowing like a jet-engine. Time for a fan replacement!

Luckily since these days, much quieter fans have been developed during the last 30 years – so let’s just swap the fan and… ahhh, silence. I did that with my Sun Blade 150 and it worked great!

…well, it’s actually not that simple all the time.

Blown by the wind

System cooling was handled a bit different back in the 80’s and 90’s. Practically there were just 3 levels of cooling:

- None – convection had to do the job.

- One for all – one fan cooled the whole system

- Insane – Either huuuuuge Fans (>8″) or some mad-scientist liquid-cooling was used. I won’t touch these in this post…

The “no fan” class were all so-called home-computers and the lower-end models of the early 16-bit machines like the ATARI ST, Commodore Amiga 500 or the first Apple Macintoshes (Steve Jobs was fanatic about convection cooling).

The most prominent “single fan” family members were office PCs up to the 486-class as well as any desktop/deskside 68k Apple Macintosh. All these had one fan sitting in their power-supply, blowing the warm air out to the back of the case.

Please mind the warm air. We’re not talking hot streams of death-rays here. While CPUs weren’t a big heat-source issue (until the advent of the i486/50) passive heatsinks were sufficient to cool them by the air-flow/draft through the case created by the PSU.

For such Personal Computer systems it can be perfectly fine to replace some old, noisy fans with recent high-tech whirls. Especially if the PSU was also replaced by something more modern (like I did with my Quadra 950) producing less heat than the original one.

This is a totally different story when it comes down to workstations.

An en-vogue (UNIX) workstation back in the days was mostly designed using a relatively small pizza-box sized case, nicely snuggling underneath a monstrous 21″ CRT. To name just a few there were

- SUN SparcStation 1 to 20

- SGI Indy

- Digital VAX/DECstation

- Many HP PA-RISC 7xx

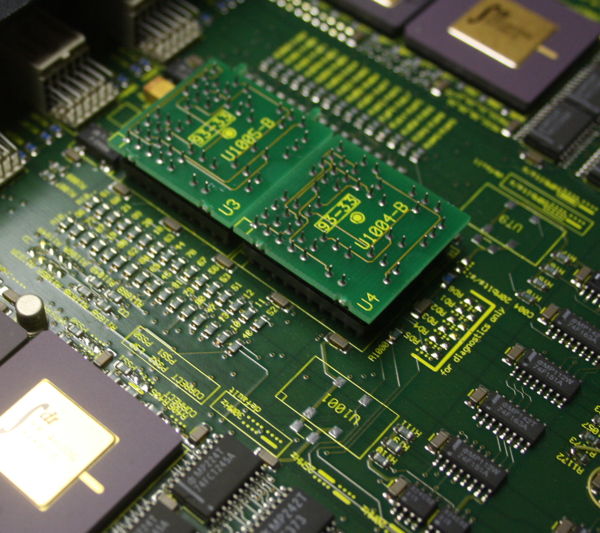

These boxes were cramped (hard-drives, expansion cards, lots of RAM) and their high-end processors ran much hotter than those x86 and 68k in personal computers.

Surprisingly none of them had a dedicated CPU fan mounted – instead they all relied on the power of the fan installed in the PSU.

Under pressure

Searching the web, you will find many texts recommending to put a quieter PC into your workstation. Vintage-me says: Don’t!

In case of workstations (pun intended!) a new indicator is needed in the game of fan replacement.

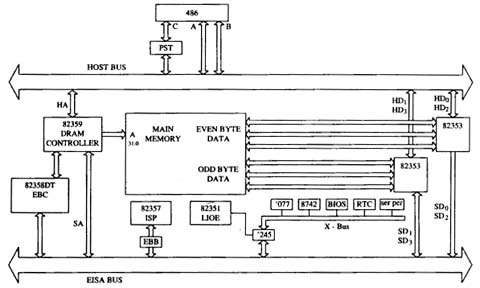

While the ‘PC world’ just looks at the CFM value (cubic feet per minute, i.e. airflow) as a performance indicator, workstation owners need to check the static pressure delivered by a fan. This is measured in mm/H20 (millimeter of water) and means how strong is a fan pulling air over obstacles and/or through venting slits etc. – think vacuum cleaner.

In consequence, two fans having about the same CFM value might be completely different when it comes down to static pressure. This is a nice table I found on the web comparing some high-performance fans with standard PC ones and the Papst 8412N is a good example of what I just wrote: The much liked NF-A8 has just 25% less CFM but only half the mm/H20:

| Fan | Airflow [CFM] | Static pressure [mmH2O] | RPM | Noise [dB] |

|---|---|---|---|---|

| Panaflo FBA08A12U1A | 46.9 | 4.8 | 3450 | 38.2 |

| EBM Papst 8412N | 40.6 | 4 | 3100 | 32.0 |

| Noctua NF-A8 FLX | 30 | 1.96 | 2000 | 16.1 |

| Noctua NF-R8 | 31 | 1.4 | 1800 | 17.1 |

| Arctic F8 | 31 | 1 | 2000 | 20 |

That power naturally comes at a price: More revs and much more noise… which is inevitable at the given mm/H20 power.

What’s cooking?

So what happens if I chose the wrong fan?

If a low-pressure fan is placed in an airflow path with lots of obstacles, the fan’s airflow will reduce and it will cool only the nearby components, but won’t have enough juice to suck heat from parts further away.

This means it will only cool (parts of) the power supply and the rest of the workstation will be more-or-less cooled by convection and the internal temperature will accumulate. Running such a machine for a longer duration will lead to ‘effects’. From errors to crashes, even smoke and finally destruction.

“C’mon, that’s folklore, Axel!” – Not a bit my friend.

I just had this experience when I thought that my MIPS RS2030 workstation could do just fine with a somewhat more silent, recent fan. The original one is/was a Delta AFB0812HH – a hellish loud fan. But even a Noctua NF-A8 with a mm/H2O of nearly 2 made the small MIPS workstation unstable. First the PSU housing got really warm in the middle (switching regulators are screwed onto it there) and after 30 minutes of torture (compiling code) I got more and more SCSI I/O errors until the system completely froze.

Changing the fan back to the noisy one everything ran rock-solid. Quod erat demonstrandum!

So what should I do?

There’s no general advise to follow. If you want to keep your original PSU it might be possible to use a more silent fan for just the PSU and add one or more fans caring for the case ventilation.

Your milage may vary and multiple modern fans -which also need to be mounted somehow- might add up producing the same amount of noise like the single original did.

The cleanest solution is replacing the original PSU innards by more modern & smaller parts which then draw less power and therefore dissipate less heat, requiring less cooling.

This is especially advisable if you have the feeling that the original PSU gives fist signs of ageing (smell, heat, buzzing). Better safe than sorry!